I did some experimenting last night using flat plates after watching a video about X plates.

Here’s what I did,

All tests used the same electrolyte/catalyst, a solution of 1/4tsp lye in 2 L of distilled water.

All tests used a 200ah 12v battery

#plates,plate size,elect conf, voltage reading, amp reading

2 – 2x4x.125 SS plates, +-, + to one, neg to other, 12v, 1.9a

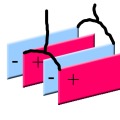

4 – 2x4x.125 SS plates, +-+-, in parallel 12v, 3.8a

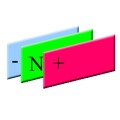

3 – 2x4x.125 SS plates, +N-, 12v, 1a

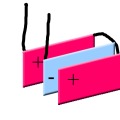

4 -2x4x.125 SS plates, +-+-, in series, 12v, 2a

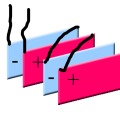

3 -2x4x.125 SS plates, +-+, 12v, 2a

3 -2x4x.125 SS plates,-+-, 12v, 2a

Hope this will help on figuring out designs, and electric configurations, I didnt get output readings, but will work on a test rig to do just that, and maybe be able to add more plate configurations to this list.

If you have similar test data why not post it, it may just help someone solve a problem.

Filed under: Cell Type, Output testing | Tagged: elect config, minus, neutral, plate config, plus |

I just noticed something on the above plate configurations, the series and parallel circuits at first thought are 2 cells of +- each, but not really, since there is no insulating cell spacers, there are three cells, +-, -+, +-

the same with the +-+, and -+- cells, are actually 2 cells of +-, and -+ for each one.

In the series cell there should be a voltage drop at each cell, in this one there should be 6v on each cell, I never measured it, but it should be there.

The parallel circuit should have 12v on each cell, but increases amperage by 2x.

All my research says you need 1.5-2v per cell to create separation from water, so at most you would not want more than 6 cells on a 12v system in parallel. and if 1 cell draws 2 amps, and 2 cells draw 4a, 3 cells should draw 6a, 4 cells should draw 4a, and 6 cells should draw 12a with 2v per cell.

Now is when production per cell should be measured, because the question now arises ‘is there 6x hho production?’

How about 6 cells in series? or combinations of 3×2,2×2,4×2,6×2 2×3,2×4,2×6 (parallel&series)??

This is a great article and very helpful.

Was thinking of doing these types of test my self. However I was going to look more deeply in to using Neutral plates

e.g.

+N-

N+N-N

+NN-

N+NN-N

As I’ve seen many people use this configuration and get good results with very little Volts & Amps

Keep up the good work. Love the site, especially the Cell Types

PaulK,

I did try N+N-N pattern once earlier and the outer N plates did nothing at all, did even produce on the outer sides of the + and – plates.

daveand5

For neutral plates to work they must be energised from within the field of current flow running between the Positive and negative plates, this is why your outer neutral plates were ineffective,

cheers Roscoe.

i have been doing a lot of reserch on the best possible plate config and have come up with a lot of diff answers. to get a high production rate try

+N-N+N- It appears that this works best without drawing a high amp rating. i will give it a twirl and let you all know the results. if anyone else has what appears to be the best config please let us all know

I tried yesterday a differnt plate config. 13 plates

N-N+N-N-N+N-N

I am only running 8-9 volts, and I think 19 amps with this design. (My multimeter can measure voltage, but I am only fused for 10 amps, so I do not know how accurate my amp reading is). It ws interesting to see that it did take the 12 volts offered.

I was getting production across the entire cell. I was concerned with previous designs that the amps were to high and it was getting too hot.

-N+N-N+N-N+N-

This design only showed production from the 2 inner negative cells, and not from the end.

Still working it out, my biggest problem is plate spacing. I do not know how to isolate the plates other using wire grommets for my stainless stell bolts. I am unable to find nylon bolts in this town.

If you intend to run this cell in a car run 12v, a car running usually is 13.5v.

As for spacing, try wire ties, the ones I have measure about .050″ or try using acetate or poly on the sides of the plates, use a Dremel tool or router to groove them at the spacing you need so that plates are set into the grooves, this will help insulate the edges, preventing some ‘voltage leaking’, and promote a vertical water flow assisting removal of the bubbles from the plates.

Plastic bolts are usually in a decent hardware such as Tru Value, Lowes, Home depot, etc but dont expect a huge selection, and you may have to order on line. Often times I have had to resort to nylon bushings to insulate the bolt, sacrificing a little plate area (the larger hole), from the bolt, sometimes its easier to use a small pvc pipe cut to the right length as a insulating bushing. (plastic tubing too)

Has anyone tried an underwater fan (think aquarium motor) to stir the water current enough to force the bubbles off of the plates, or would the electricity required to power the fan negate any benefit of additional HHO production?

Some people have used pumps aquarium and others to move the bubbles, but they haven’t really posted results anywhere as to if it helped. Using a natural flow, (hot to cold, bottom to top, bubbles moving the water, ) does seem to work good. The higher the tank is from the top of the cell the better the flow. Also adds cooling to the cell, increasing time to heat the liquid, and maintaining a lower temp longer. Some use check valves to force the liquid one direction. I used different size holes, larger at the top, and got no reverse flow unless the top hose was pinched closed.

I’ve seen a YouTube video of a guy who uses stainless steel wool, and a series of pumps to move the water (KOH solution) in a closed loop, even having it run through a radiator to cool down. If I recall, the amperage used was almost 200amps @12V. His HHO production was incredible (30L/min?), however at that power usage, it definetly wasn’t overunity.

I had a 10 plate config that went +-+-+-+-+- and got great productions rating….for 2 minutes! I was using a 16-gauge wire in my car to power my unit and would blow a 30a fuse in just a few minutes! The wires would get really hot to and one even started smoking. This even happened with plain tap water and no electrolyte added! When i did have the electrolyte solution in the cell it did wonders for a short period. Since i kepy blowing fuses i juimped up to a 10 gauge wire and the same thing kept happening.

I am going to try a new setup now and stick with having a neutral plate in the config. THIS IS A MUST!! I will let you all know my results with this and keep you updated.

Lets all show BIG OIL WHATS UP!

Jeff, get hold of an amp gauge, and set the electrolyte starting with small amount, and slowly add to where you want the amps to be. And remember the amps will climb the warmer the the liquid gets. Also get a circuit breaker that will plug into your fuse holder, its a cash saver.

If your using tap water or well water you will have mineral contaminants already in it (a catalyst), distilled water doesn’t.

And that will probably explain the high amp draw.

Hi there from the UK,

We are in deep shit on enErgy prices in the UK!

i UNDERSTAND THAT, if i charge a deep cell battery from whatever means, I can then use it through an invertor to power my household bits and pieces.

You guys are talking about using plates of Stainless STEEL?…BOTH IDENTICAL, BUT USING ONE AS A POSITIVE AND ANOTHER AS A NEGATIVE to get voltage and high amperage CAN YOU DO THIS?..appears you can?

I take it then if I buy SSteel, cut it to a certain size, connect the plates in such a manner, emerse it in an electrolite, I can then see 12 volts?…

If this is so, can you make it clearer for us people from the Mother country that are stuck with Brown guy that does nothing but spout off, somewhat like Bush??…sorry to bring in politics?..but I would seriously like to try this as an English politician, for all the hot air I listen to, it’s good to speak to the people that are tuned in?

Now I don’t speak British but I’m assuming that when you say bits and pieces you are reffering to gas appliances. Im no expert but in theory it is possible, however with any amount of contained HHO gas the risk of explosion is high and a very dangerous thing to have in your living space without proper ventilation. If you want to experiment try this outside until you know its safe and use old appliances so you don’t destroy your hardware. Good luck let us know how your tests go

Stan,

apparently you missed a little bit in your reading, we’re not making 12v dc, were using 12v dc to produce hydroxy gas.

And yes you can use an inverter to power many devices if the inverter and batteries are large enough.

Crashandburn is right about the dangers of the gas, it is a perfect mix of gasses ready to ignite at the least excuse, so use with caution if testing on appliances.

sorry about your confusion, we all have those days, some more than others…..